Learn about rapid prototyping with 3D printing and how it can help you speed up the product development process. This article provides valuable insights on how to optimize your prototyping process and improve the quality of your products.

Table of Contents:

I. Introduction

II. What is Rapid Prototyping?

III. Benefits of Rapid Prototyping with 3D Printing

IV. How to Get Started with Rapid Prototyping

V. Tips for Effective Rapid Prototyping

VI. Conclusion

I. Introduction

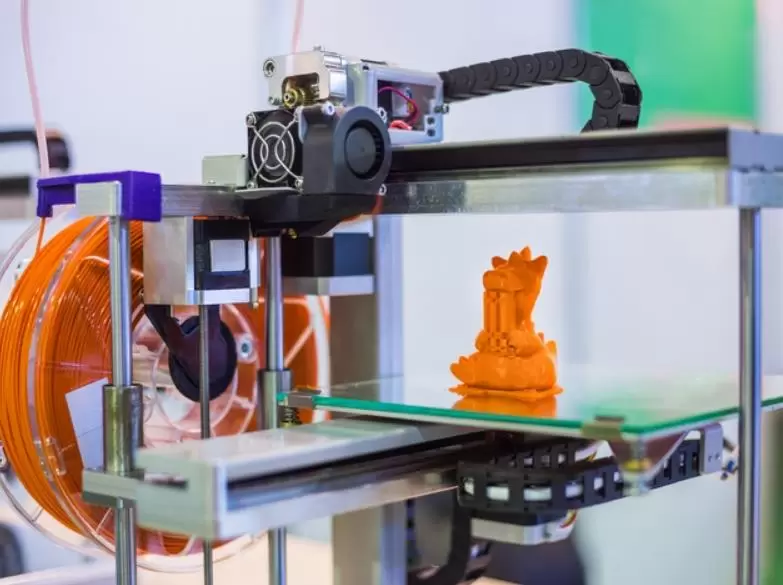

Rapid prototyping has changed the way product development is done today. With the advent of 3D printing, it has become easier and faster to create prototypes than ever before. In this article, we will explore the benefits of rapid prototyping with 3D printing and provide valuable insights on how to optimize your prototyping process.

II. What is Rapid Prototyping?

Rapid prototyping is a process of creating a physical model of a product or part in a short span of time. This process allows designers and engineers to test and refine their ideas quickly. Rapid prototyping with 3D printing involves using a computer-aided design (CAD) software to create a 3D model of the part or product. This 3D model is then sent to a 3D printer which creates the physical prototype.

III. Benefits of Rapid Prototyping with 3D Printing

There are several benefits to using rapid prototyping with 3D printing, including:

- Speed: Traditional prototyping methods can take weeks or even months to create a prototype. With 3D printing, prototypes can be created within a matter of hours or days.

- Cost-Effective: 3D printing allows for the creation of complex designs at a fraction of the cost of traditional prototyping methods.

- Customization: With 3D printing, it is easy to customize the design of a product or part to meet specific requirements.

- Quality: Rapid prototyping with 3D printing produces prototypes with high accuracy and precision, leading to improved quality of the final product.

IV. How to Get Started with Rapid Prototyping

To get started with rapid prototyping with 3D printing, you will need the following:

- CAD software: This software is used to create a 3D model of your product or part.

- 3D printer: You will need a 3D printer to create the physical prototype.

- Filament: The material that is used to create the model in 3D printing is called filament. You will need to choose the appropriate filament for your product or part.

- Slicing software: This software is used to prepare the 3D model for printing.

V. Tips for Effective Rapid Prototyping

- Start with a simple design: It is advisable to start with a simple design when getting started with 3D printing. This will help you understand the process better and avoid wasting time and money on failed attempts.

- Choose the right materials and printing parameters: Choosing the right materials and printing parameters is essential for getting a high-quality print.

- Test and refine: Testing and refining your design is crucial for improving the quality of your product. This involves creating multiple prototypes and making necessary changes until you achieve the desired result.

VI. Conclusion

Rapid prototyping with 3D printing is a game-changer in the product development industry. It enables designers and engineers to create prototypes quickly and cost-effectively. As with any new technology, there is a learning curve involved in getting started with 3D printing. However, with practice and dedication, you can master the art of rapid prototyping and build better products.