Table of Contents:

- Introduction to Precision CNC Machining

- CNC Machining vs. Conventional Machining

- Types of CNC Machines

- Materials Used in CNC Machining

- Precision CNC Machining Processes

- Advantages of Precision CNC Machining

- Applications of Precision CNC Machining

- Quality Control in Precision CNC Machining

- Future of Precision CNC Machining

- Conclusion

-

1.Introduction to Precision CNC Machining

Precision CNC machining refers to the manufacturing process that involves using Computer Numerical Control (CNC) machines to create highly accurate and complex parts and components. CNC machines are capable of producing parts with extremely tight tolerances, which makes them ideal for use in industries that require high precision, such as aerospace, medical devices, and automotive.

-

2.CNC Machining vs. Conventional Machining

In conventional machining, the operator uses manual tools to shape and cut the material into the desired shape. CNC machining, on the other hand, involves using a computer-controlled machine to perform the same operations. CNC machines are more precise and efficient than conventional machines, and they can produce more complex parts in a shorter amount of time.

-

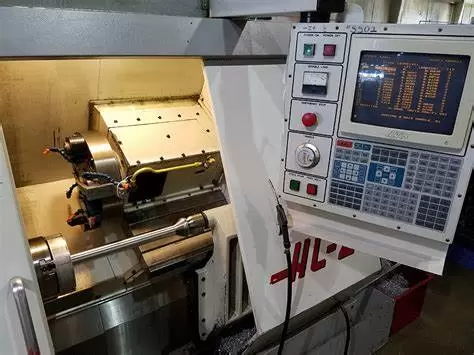

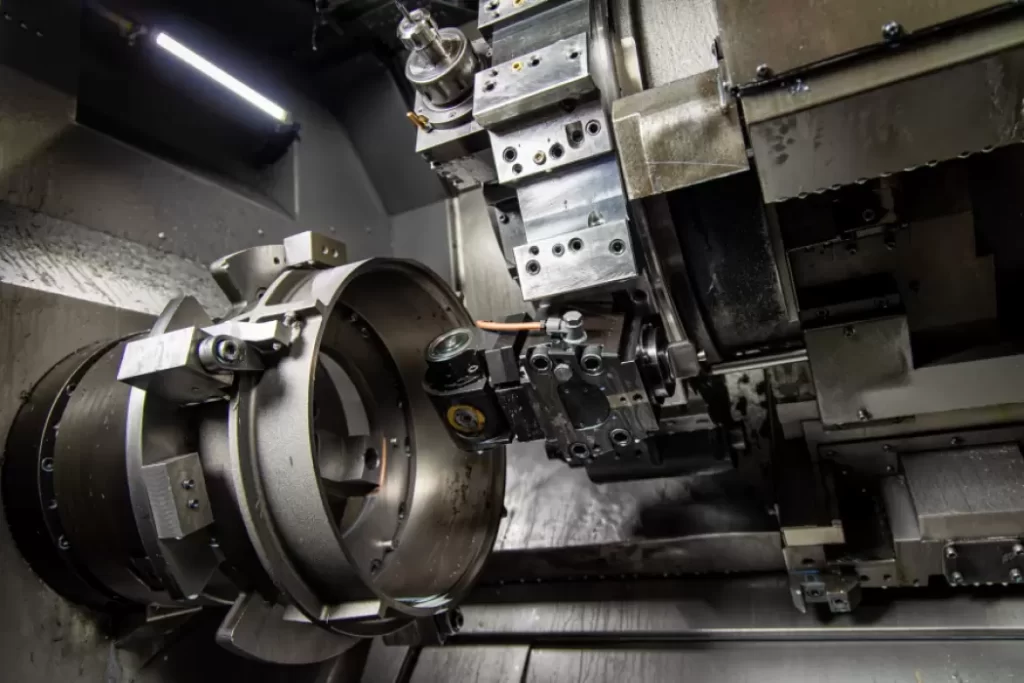

3.Types of CNC Machines

There are several types of CNC machines available, each with its unique features and capabilities. The most common types of CNC machines include:

- CNC Milling Machines: These machines use rotating cutting tools to remove material from a workpiece and create the desired shape.

- CNC Turning Machines: These machines use a rotating workpiece and a stationary cutting tool to shape the material.

- CNC Drilling Machines: These machines use a rotating drill bit to create holes in the material.

- CNC Grinding Machines: These machines use abrasive wheels to grind and shape the material.

- CNC EDM Machines: These machines use electrical discharges to remove material from the workpiece and create the desired shape.

-

4.Materials Used in CNC Machining

CNC machining can be used to create parts and components from a wide variety of materials, including metals, plastics, composites, and ceramics. Some of the most commonly used materials in CNC machining include:

- Aluminum: A lightweight and corrosion-resistant material that is commonly used in aerospace and automotive applications.

- Steel: A strong and durable material that is commonly used in industrial applications.

- Titanium: A lightweight and strong material that is commonly used in aerospace and medical applications.

- Plastics: A versatile material that is commonly used in a variety of applications, including medical devices and electronics.

-

5.Precision CNC Machining Processes

There are several precision CNC machining processes that can be used to create highly accurate and complex parts and components. These processes include:

A. Turning:Turning is the process of shaping a rotating workpiece using a stationary cutting tool. This process is commonly used to create cylindrical parts, such as shafts and bearings.

B. Milling:Milling is the process of removing material from a workpiece using a rotating cutting tool. This process is commonly used to create flat or curved surfaces on a workpiece.

C. Drilling:Drilling is the process of creating holes in a workpiece using a rotating drill bit. This process is commonly used to create holes for fasteners or to create openings for wiring and other components.

D. Grinding:Grinding is the process of using an abrasive wheel to remove material from a workpiece. This process is commonly used to create precise shapes and surfaces on a workpiece.

E. EDM (Electrical Discharge Machining):EDM is the process of using electrical discharges to remove material from a workpiece. This process is commonly used to create complex shapes and features that are difficult to machine using other methods.

-

6.Advantages of Precision CNC Machining

Precision CNC machining offers several advantages over conventional machining methods. These advantages include:

- High Precision: CNC machines can produce parts with extremely tight tolerances, which makes them ideal for use in applications that require high precision.

- Efficiency: CNC machines are faster and more efficient than conventional machines, which allows manufacturers to produce parts in a shorter amount of time.

- Flexibility: CNC machines can be programmed to produce a wide variety of parts

With Advantages of Precision CNC Machining:

- Automation: CNC machines are automated, which means that they can run continuously without the need for human intervention. This results in increased productivity and reduced labor costs.

- Consistency: CNC machines can produce parts with consistent quality, which helps to ensure that the final product meets the required specifications.

- Versatility: CNC machines can be used to create parts from a wide variety of materials, including metals, plastics, composites, and ceramics.

-

7.Applications of Precision CNC Machining

Precision CNC machining is used in a wide variety of industries, including:

A. Aerospace: CNC machining is used to create complex and highly precise parts for aircraft and spacecraft, such as turbine blades, engine components, and structural parts.

B. Medical Devices: CNC machining is used to create medical devices and implants, such as prosthetic limbs, dental implants, and surgical instruments.

C. Automotive: CNC machining is used to create parts for vehicles, such as engine components, transmission parts, and suspension components.

D. Electronics: CNC machining is used to create parts for electronic devices, such as computer components, cell phone components, and circuit boards.

E. Defense: CNC machining is used to create parts for military equipment, such as weapons, tanks, and aircraft.

If you need about Precision CNC Machining Services,You can click on the V1 Prototype website to find it:Provide Plastic And Metal Part CNC Machining Services Including:CNC Milling, CNC Turning, Rapid Drilling, CNC Grinding, CNC Cutting, Wire EDM Machining Etc.

-

8.Quality Control in Precision CNC Machining

Quality control is a critical aspect of precision CNC machining. To ensure that the final product meets the required specifications, manufacturers use a variety of quality control techniques, including:

A. Inspection Techniques: Manufacturers use a variety of inspection techniques to ensure that parts meet the required specifications. These techniques include visual inspection, dimensional inspection, and surface inspection.

B. Statistical Process Control (SPC): SPC is a method of monitoring and controlling a production process to ensure that it operates within the required specifications. Manufacturers use SPC to identify and correct process variations before they result in defects.

C. Quality Certifications: Manufacturers can obtain quality certifications, such as ISO 9001, to demonstrate that they have implemented a quality management system that meets the required standards.

-

9.Future of Precision CNC Machining

The future of precision CNC machining looks bright. As technology advances, CNC machines are becoming more advanced and capable of producing even more complex parts with higher precision. In addition, advances in software and automation are making CNC machines more efficient and easier to use.

-

10.Conclusion

Precision CNC machining is a critical manufacturing process that is used in a wide variety of industries. It offers several advantages over conventional machining methods, including high precision, efficiency, and versatility. As technology advances, CNC machines will become even more advanced and capable, which will further increase their importance in modern manufacturing.