Table of Contents:

- Introduction

- Overview of Injection Mold Manufacturing in China

- Advantages of Injection Mold Manufacturing in China

- Challenges of Injection Mold Manufacturing in China

- Choosing the Right Injection Mold Manufacturer in China

- Quality Control in Injection Mold Manufacturing in China

- Intellectual Property Protection in Injection Mold Manufacturing in China

- Shipping and Logistics for Injection Mold Manufacturing in China

- Cost Considerations for Injection Mold Manufacturing in China

- Conclusion and Future Outlook

1.Introduction

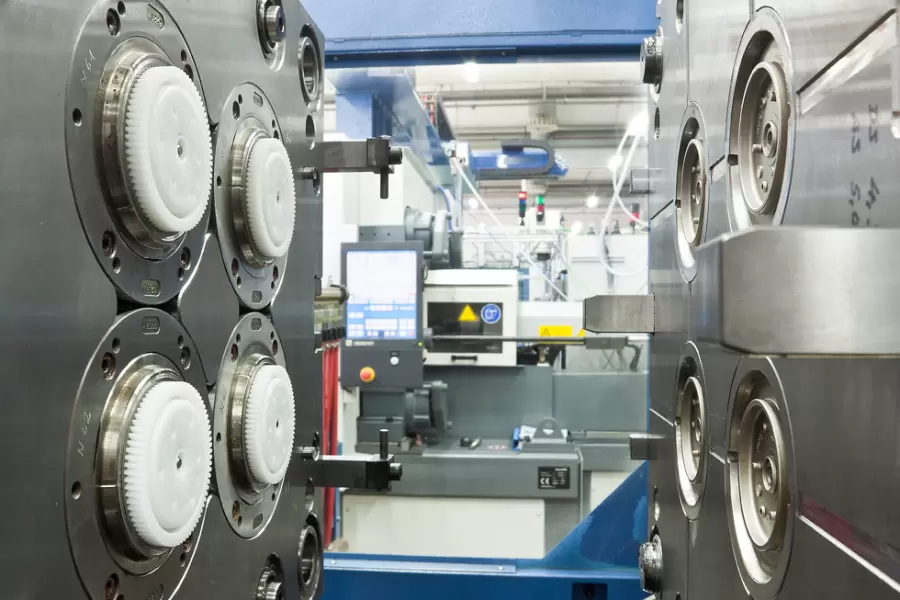

Injection molding is a widely used manufacturing process in various industries, including automotive, electronics, medical devices, and consumer products. China has become a global hub for injection mold manufacturing, with many companies outsourcing their production to Chinese manufacturers.

In this comprehensive guide, we will provide an overview of injection mold manufacturing in China, including its advantages and challenges. We will also discuss the factors that should be considered when choosing the right injection mold manufacturer in China, as well as quality control and intellectual property protection measures. Additionally, we will cover shipping and logistics, as well as cost considerations. By the end of this guide, you will have a better understanding of the injection mold manufacturing process in China, and be able to make informed decisions about outsourcing your production to a Chinese manufacturer.

-

2.Overview of Injection Mold Manufacturing in China

Injection mold manufacturing in China has become increasingly popular due to the country’s lower labor costs and extensive manufacturing capabilities. The process involves creating a custom mold design for a particular product, which is then used to produce the final product by injecting molten plastic or other materials into the mold.

Chinese injection mold manufacturers have a wide range of capabilities and can produce molds for various types of products, including large and complex automotive parts, electronic components, and consumer goods. Additionally, Chinese manufacturers are known for their flexibility in customizing molds according to the customer’s requirements.

The injection mold manufacturing industry in China is highly competitive, with many manufacturers offering competitive pricing and fast turnaround times. However, the quality of the molds produced can vary widely, with some manufacturers producing low-quality molds that may require frequent repairs or replacement.

To ensure high-quality molds, it is essential to work with a reputable and experienced injection mold manufacturer in China that has a proven track record of producing quality molds. In the next section, we will discuss the advantages and challenges of injection mold manufacturing in China.

-

3.Advantages of Injection Mold Manufacturing in China

There are several advantages to injection mold manufacturing in China, including:

- Lower labor costs: China’s labor costs are significantly lower than those in many other countries, making it an attractive option for manufacturers looking to reduce production costs.

- Extensive manufacturing capabilities: Chinese injection mold manufacturers have advanced equipment and technology, allowing them to produce high-quality molds for a wide range of products.

- Flexibility and customization: Chinese manufacturers are known for their flexibility in customizing molds according to the customer’s requirements, making it easier to create molds that meet specific product specifications.

- Fast turnaround times: The injection mold manufacturing industry in China is highly competitive, with many manufacturers offering fast turnaround times, allowing customers to receive their molds quickly.

- Access to a large pool of skilled workers: China has a large pool of skilled workers who have experience in injection mold manufacturing, making it easier to find qualified workers for the job.

- Favorable government policies: The Chinese government offers several incentives to attract foreign investors, including tax breaks and subsidies, making it easier and more cost-effective for foreign companies to set up manufacturing facilities in China.

-

4.Challenges of Injection Mold Manufacturing in China

While there are many advantages to injection mold manufacturing in China, there are also several challenges that should be considered, including:

- Quality control: The quality of the molds produced by Chinese manufacturers can vary widely, with some manufacturers producing low-quality molds that may require frequent repairs or replacement. It is important to work with a reputable and experienced manufacturer that has a proven track record of producing high-quality molds.

- Intellectual property protection: Intellectual property protection in China can be a challenge, with many manufacturers engaging in intellectual property theft or infringement. It is essential to take steps to protect your intellectual property and work with a manufacturer that has strong intellectual property protection policies in place.

- Communication and language barriers: Communication can be a challenge when working with Chinese manufacturers, particularly if there are language barriers or cultural differences. It is important to have clear communication channels and work with a manufacturer that has English-speaking staff or provides translation services.

- Shipping and logistics: Shipping and logistics can be complicated when working with Chinese manufacturers, particularly if the manufacturer is located in a remote area. It is important to work with a manufacturer that has experience in international shipping and logistics.

- Political and economic instability: China’s political and economic situation can be unstable at times, with changes in government policies or economic conditions potentially affecting manufacturing operations. It is important to monitor the political and economic situation in China and have contingency plans in place.

-

5.Choosing the Right Injection Mold Manufacturer in China

Choosing the right injection mold manufacturer in China is a critical step in ensuring that you receive high-quality molds that meet your product specifications. Here are some factors to consider when choosing a manufacturer:

- Experience and reputation: Look for a manufacturer that has a proven track record of producing high-quality molds and has experience working with companies in your industry.

- Quality control measures: The manufacturer should have a rigorous quality control process in place to ensure that the molds produced meet your product specifications and are of high quality.

- Intellectual property protection: The manufacturer should have strong intellectual property protection policies in place and be willing to sign a non-disclosure agreement to protect your intellectual property.

- Communication and language skills: The manufacturer should have English-speaking staff or provide translation services to ensure that communication is clear and effective.

- Manufacturing capabilities: The manufacturer should have the equipment and technology necessary to produce molds that meet your product specifications, and should be able to customize molds to meet your specific requirements.

- Shipping and logistics: The manufacturer should have experience in international shipping and logistics and should be able to provide competitive shipping rates and fast turnaround times.

- Cost: While cost should not be the only factor considered, it is important to choose a manufacturer that offers competitive pricing without sacrificing quality.

By carefully considering these factors and conducting thorough research on potential manufacturers, you can find a reputable and experienced injection mold manufacturer in China that can meet your production needs.

Click on the V1 Prototype website to gain more information.

-

6.Quality Control in Injection Mold Manufacturing in China

Quality control is a critical aspect of injection mold manufacturing in China, as the quality of the molds produced can vary widely among manufacturers. Here are some key considerations for ensuring quality control in injection mold manufacturing in China:

- Quality control procedures: The manufacturer should have a comprehensive quality control process in place that covers all aspects of mold production, from design to delivery. The process should include checks at each stage of production to ensure that the molds meet your product specifications and are of high quality.

- Material selection: The manufacturer should use high-quality materials that are appropriate for your product and production requirements. The materials should meet industry standards and be sourced from reputable suppliers.

- Equipment and technology: The manufacturer should have advanced equipment and technology that can produce high-quality molds with tight tolerances and consistent results.

- Experienced staff: The manufacturer should have experienced staff who are knowledgeable about injection mold manufacturing and can ensure that the molds meet your product specifications.

- Quality certifications: The manufacturer should have quality certifications such as ISO 9001 or TS 16949, which indicate that they have a robust quality management system in place.

- Testing and inspection: The manufacturer should conduct testing and inspection on the molds to ensure that they meet your product specifications and are of high quality. This may include visual inspection, dimensional inspection, and functional testing.

- Communication: Communication is key to ensuring quality control in injection mold manufacturing in China. The manufacturer should have clear communication channels and be responsive to your inquiries and concerns.

By working with a manufacturer that has a strong focus on quality control, you can ensure that the molds produced meet your product specifications and are of high quality.

-

7.Intellectual Property Protection in Injection Mold Manufacturing in China

Intellectual property (IP) protection is an important consideration in injection mold manufacturing in China, as there have been cases of IP infringement and theft. Here are some key steps you can take to protect your intellectual property when working with injection mold manufacturers in China:

- Conduct due diligence: Before choosing a manufacturer, conduct thorough research to ensure that they have a reputation for protecting intellectual property. Look for manufacturers with a proven track record of working with companies in your industry, and ask for references from previous clients.

- Sign a non-disclosure agreement (NDA): A non-disclosure agreement is a legal contract that prohibits the manufacturer from disclosing any confidential information about your product or technology. Make sure that the NDA is specific to your product and includes clear terms regarding the duration of the agreement and the consequences of a breach.

- Register your patents and trademarks: Register your patents and trademarks with the appropriate Chinese authorities to protect your intellectual property rights. This will provide legal recourse in the event of any infringement.

- Monitor your IP: Regularly monitor your intellectual property to ensure that it is not being infringed upon. This may include conducting internet searches, attending trade shows, and working with local attorneys to investigate any suspected infringement.

- Take legal action: If you discover that your intellectual property has been infringed upon, take legal action to protect your rights. This may include filing a lawsuit in Chinese courts or working with Chinese authorities to enforce your intellectual property rights.

By taking these steps to protect your intellectual property, you can minimize the risk of IP infringement and theft in injection mold manufacturing in China. It is important to work with a manufacturer that is willing to sign a non-disclosure agreement and has a strong reputation for protecting intellectual property.

-

8.Shipping and Logistics for Injection Mold Manufacturing in China

Shipping and logistics are critical aspects of injection mold manufacturing in China, as the molds produced need to be shipped to your location in a timely and cost-effective manner. Here are some key considerations for shipping and logistics when working with injection mold manufacturers in China:

- Shipping options: The manufacturer should have experience in international shipping and be able to provide a range of shipping options to meet your needs. This may include air freight, sea freight, or courier services.

- Customs clearance: The manufacturer should have experience with customs clearance procedures in your country and be able to provide the necessary documentation to ensure that the molds are cleared through customs without delay.

- Packaging: The molds should be packaged securely to prevent damage during shipping. The manufacturer should use appropriate packaging materials and techniques to ensure that the molds arrive at your location in good condition.

- Lead time: The manufacturer should provide a clear timeline for production and shipping to ensure that the molds arrive at your location within the required timeframe.

- Communication: Communication is key to ensuring that the shipping and logistics process runs smoothly. The manufacturer should have clear communication channels and be responsive to your inquiries and concerns.

- Cost: The manufacturer should provide competitive shipping rates and work with you to minimize shipping costs without sacrificing quality.

-

9.Cost Considerations for Injection Mold Manufacturing in China

Cost is a major consideration when it comes to injection mold manufacturing in China. Here are some key cost considerations to keep in mind when working with injection mold manufacturers in China:

- Mold design: The cost of injection mold manufacturing in China is largely influenced by the complexity of the mold design. Complex molds require more time and resources to produce, which increases the cost. To minimize costs, consider simplifying the mold design without compromising on quality or functionality.

- Material selection: The choice of materials can significantly impact the cost of injection mold manufacturing. While some materials may be cheaper upfront, they may not be durable enough for long-term use. Choose materials that are high quality and appropriate for your product and production requirements.

- Quantity: The quantity of molds ordered can impact the overall cost. Manufacturers may offer discounts for larger orders, so it’s important to consider the total quantity needed before placing an order.

- Production volume: The volume of production can also impact the overall cost. High-volume production may require additional resources and equipment, which can increase the cost. However, producing a larger quantity of molds can also lead to economies of scale and reduce the cost per unit.

- Labor costs: The cost of labor in China is generally lower than in many other countries, which can make injection mold manufacturing in China more cost-effective. However, it’s important to ensure that the manufacturer pays fair wages to their workers and does not compromise on quality to cut costs.

- Shipping and logistics: The cost of shipping and logistics can vary widely depending on the shipping method, distance, and other factors. It’s important to work with a manufacturer that can provide competitive shipping rates and minimize shipping costs where possible.

-

10.Conclusion and Future Outlook

Injection mold manufacturing in China offers many advantages, including low labor costs, high-quality manufacturing, and a wide range of production capabilities. However, there are also challenges to be aware of, such as intellectual property concerns and quality control issues. To ensure a successful partnership with an injection mold manufacturer in China, it’s important to carefully choose a manufacturer with a proven track record of quality and reliability, and to establish clear communication channels and quality control procedures.

Looking to the future, injection mold manufacturing in China is likely to continue to be a popular choice for companies seeking cost-effective and high-quality manufacturing solutions. With advances in technology and materials, injection mold manufacturers in China will be able to produce increasingly complex and high-quality molds, while maintaining competitive pricing. However, it will also be important for manufacturers to stay up-to-date on intellectual property laws and invest in quality control measures to ensure that they remain a reliable and trusted partner for their customers.

Overall, injection mold manufacturing in China offers many benefits for companies seeking cost-effective and high-quality manufacturing solutions. By working with a trusted and experienced manufacturer, companies can access the benefits of Chinese manufacturing while minimizing the risks and challenges associated with working in a foreign market.

Injection molding is a widely used manufacturing process that can produce plastic parts with complex shapes and high precision. However, injection molding also involves many challenges and risks, especially when outsourcing to China. This article will provide an overview of the advantages, challenges, and key considerations for navigating injection mold manufacturing in China.

One of the main advantages of injection mold manufacturing in China is the lower cost compared to other countries. China has a large and competitive market of injection mold suppliers, which can offer lower prices for materials, labor, and overhead. Additionally, China has a well-developed infrastructure and logistics network, which can facilitate the transportation and delivery of injection molds and parts.

However, injection mold manufacturing in China also poses some significant challenges that require careful planning and management. Some of the common challenges include:

- Quality control: The quality of injection molds and parts can vary widely depending on the supplier's capabilities, equipment, and quality standards. Poor quality can lead to defects, rework, delays, and customer dissatisfaction. Therefore, it is important to conduct thorough research and due diligence on potential suppliers, as well as regular inspections and audits throughout the production process.

- Communication: Language and cultural barriers can cause misunderstandings and miscommunication between customers and suppliers, which can affect the design, specifications, and expectations of injection molds and parts. Therefore, it is essential to have clear and detailed communication channels, such as contracts, drawings, samples, feedback mechanisms, and translators.

- Intellectual property protection: The risk of intellectual property theft or infringement is high in China, as some suppliers may copy or sell injection molds or parts without authorization. Therefore, it is crucial to protect intellectual property rights by registering trademarks, patents, and designs in China, as well as using non-disclosure agreements, confidentiality clauses, and security measures.

- Legal compliance: The laws and regulations governing injection mold manufacturing in China are complex and constantly changing, which can affect the import/export procedures, taxes, tariffs, certifications, and environmental standards. Therefore, it is advisable to consult with local experts or lawyers to ensure legal compliance and avoid penalties or disputes.

To successfully navigate injection mold manufacturing in China, customers need to consider some key factors that can influence the outcome of the project. Some of the key considerations include:

- Design optimization: The design of injection molds and parts should be optimized for manufacturability, functionality, and cost-effectiveness. This can involve using standard components, reducing complexity, minimizing waste, enhancing durability, and improving aesthetics.

- Material selection: The material of injection molds and parts should be selected based on the performance requirements, such as strength, stiffness, toughness, heat resistance, chemical resistance, color stability, and biocompatibility. The material should also be compatible with the injection molding process and equipment.

- Supplier selection: The supplier of injection molds and parts should be chosen based on their reputation, experience, expertise, capacity, quality system, delivery time, price, and service. The supplier should also be able to provide technical support, after-sales service, warranty, and maintenance.

- Project management: The project of injection mold manufacturing in China should be managed by a dedicated team that can coordinate the activities of customers and suppliers. The team should also monitor the progress of the project using key performance indicators (KPIs), such as cost, quality,

timeframe,and customer satisfaction.

Injection mold manufacturing in China can offer many benefits for customers who are looking for a cost-effective and efficient way to produce plastic parts. However,it also requires careful preparation,planning,and execution to overcome the challenges,risks,and uncertainties involved. By following the above-mentioned advantages,challenges,and key considerations,customers can achieve a successful outcome for their injection mold manufacturing project in China.