Introduction

The concept of 3D printing, also known as additive manufacturing, has its roots in several decades of research and development. The journey of 3D printing began with visionary ideas and has evolved into a transformative technology that has revolutionized manufacturing processes across various industries. In this blog post, we will take a journey through the brief history of 3D printing, exploring key milestones and breakthroughs that have shaped the landscape of additive manufacturing.

1. The Birth of 3D Printing (1980s)

The origins of 3D printing can be traced back to the 1980s when a process called Stereolithography (SLA) was developed by Charles W. Hull. Hull, often referred to as the "father of 3D printing," co-founded 3D Systems Corporation and filed a patent for SLA technology in 1984. SLA involved using a UV laser to solidify liquid photopolymers layer by layer, creating three-dimensional objects. This revolutionary concept laid the foundation for the future of additive manufacturing.

2. The Rise of Selective Laser Sintering (SLS) (1980s)

In the late 1980s, Carl Deckard and Joe Beaman at the University of Texas at Austin developed Selective Laser Sintering (SLS). SLS utilized a high-powered laser to fuse powdered materials, such as nylon, into solid layers. This process eliminated the need for liquid resins and allowed for the use of a wider range of materials in 3D printing, expanding its potential applications.

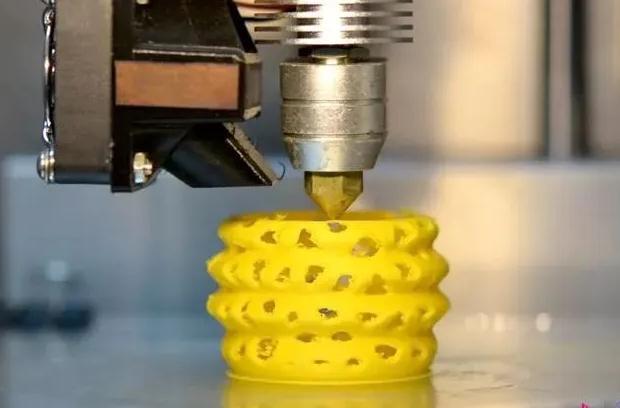

3. Fused Deposition Modeling (FDM) Emerges (1980s)

In 1988, Scott Crump, the co-founder of Stratasys, introduced Fused Deposition Modeling (FDM). FDM involves extruding thermoplastic materials through a heated nozzle to build layers and create three-dimensional objects. FDM became one of the most popular 3D printing technologies due to its ease of use and wide availability.

4. Commercialization of 3D Printing (1990s)

The 1990s saw the commercialization of 3D printing technologies, making them more accessible to industries and researchers. Companies like Stratasys and 3D Systems started offering 3D printers for sale, enabling businesses to explore the potential of additive manufacturing for prototyping and product development.

5. Expanding Material Options (2000s)

In the early 2000s, research and development efforts focused on expanding the range of materials available for 3D printing. Beyond plastics and polymers, new materials such as metals, ceramics, and composites were introduced, opening up possibilities for more diverse and functional applications.

6. 3D Printing Goes Mainstream (2010s)

The 2010s marked a turning point for 3D printing as the technology gained mainstream attention and adoption. 3D printing became more affordable, and consumer-oriented 3D printers entered the market, allowing individuals and hobbyists to explore the world of additive manufacturing.

7. Advancements in Speed and Precision (2010s)

Throughout the 2010s, significant advancements were made in 3D printing technology, leading to faster printing speeds and higher precision. This progress further expanded the potential applications of 3D printing in various industries, including aerospace, healthcare, automotive, and fashion.

8. Multi-Material and Multi-Color Printing

As 3D printing technology matured, the ability to print with multiple materials and colors simultaneously became possible. Multi-material and multi-color printing allowed for the creation of more complex and realistic prototypes and end-use products.

9. Large-Scale 3D Printing

Recent years have witnessed developments in large-scale 3D printing, enabling the production of oversized objects and architectural structures. Large-scale 3D printing holds promise for applications in construction, aerospace, and marine industries.

10. Advancements in Bioprinting

In the realm of healthcare, bioprinting has emerged as a cutting-edge application of 3D printing. Researchers have made strides in printing living tissues and organs, holding the potential to revolutionize regenerative medicine and transplantation.

Conclusion

The history of 3D printing is a testament to human ingenuity and the pursuit of innovation. From its humble beginnings in the 1980s to its widespread adoption today, 3D printing has transformed the manufacturing landscape and unlocked new possibilities for design, prototyping, and production.

As the technology continues to advance, we can expect even more groundbreaking developments in the field of additive manufacturing. From sustainable materials to large-scale printing and bioprinting, the future of 3D printing holds great promise for reshaping industries and improving lives. V1Prototype, as a key player in the additive manufacturing space, continues to contribute to this transformative journey, pushing the boundaries of what is possible with 3D printing.

The term "3D printing" is generally used synonymously with "additive manufacturing". This was not always the case, and in 2007 3D printing and 3D printers would have been expressed as extruded materials or plastics for desktop machines. During this time, many industrial users of additive manufacturing adopted the term "additive manufacturing" or RP to refer to processes such as laser sintering or adhesive injection processes. The term 3D printing has become particularly popular in the last decade because of the popularity of desktop printers and the maker movement. Because of its popularity in the media, these terms are now being adopted interchangeably in conversations - especially in marketing materials. Unbeknownst to them, most industrial processes still prefer additive manufacturing or AM. Other terms for 3D printing are additive manufacturing, additive processes, additive technologies, additive layer manufacturing, layer manufacturing, and free-form manufacturing.

Additive manufacturing began in the early 1980s when Dr. HideoKodama applied for the first patent in Japan in 1980, but it was not granted because he did not submit a perfected application within a year. Four years later, in 1984, ChuckHull applied for a patent for stereolithography (SLA). chuckHull went on to found 3DSystems and is the inventor of the STL mesh file format that is still used on most 3D printing platforms. Stereolithography is a process that creates parts based on selectively curing resin layer by layer, creating a cross-section of 3D geometry one at a time. The UV-sensitive resin reacts with the UV laser, causing it to harden where it is subjected to impact.

In 1987, CarlDeckard filed a patent for selective laser sintering, which was later granted in 1989. Selective laser sintering (SLS) is a process that melts fine plastic powder with a laser in a heated build chamber. sLS brings more versatility to end-use products because it uses thermoplastic nylon as its printing material. It was closely followed by the invention of fused deposition modeling (FDM) in 1988 by Stratasys founder S. Scott Crump. The patent was granted in 1992. Also in 1989, EOS was founded. To this day, EOS, Stratasys and 3DSystems remain major players in additive manufacturing.

In the early 1990s and early 2000s, additional technologies were invented and innovated. This encompassed Solidscape's resin printing for dewax casting, Z-Corporation's adhesive injection process for sandstone-based parts, the manufacture of paper-based layered objects offered by Helisys and its Arcam metal electron beam melting process. During this time, another major 3D printing process was developed - selective laser melting (SLM).SLM is a combination of direct metal laser sintering (DMLS created by 3DSystems), LaserCusing (the term for ConceptLaser), and direct metal laser melting (DMLM) are synonymous.

Over the past decade, from 2009 to 2019, many of the original patents of 3DSystems, Stratasys and other founding companies have expired. Along with the expiration of key patents, many other 3D printing companies have emerged in the professional, consumer and mid-range "prosumer" 3D printing space. 2011 meant the creation of Formlabs, the maker of the first consumer version of the SLA3D printer. 2013 saw the creation of Markforged, a professional consumable printer capable of embedding continuous carbon or Kevlar fibers between layers for increased stiffness. 2015 saw the launch of DesktopMetal, the first metal 3D printer. DesktopMetal first implemented a metal 3D printer that uses FDM-style extrusion and plasticized metal rods to produce metal parts. At that time, Markforged also produced a system that used a similar method to print metal.

In 2013, MakeXYZ was created to interconnect consumer desktop 3D printers with users who need parts, and Xometry was launched in 2014 to instantly price 3D models for a variety of specialized manufacturing technologies, including additive manufacturing and CNC machining services. leverages partner manufacturing companies to enable manufacturing projects purchased through Xometry's services.In 2019, Xometry implemented its consumables and finishing services to provide on-demand e-commerce services for manufacturers and partners alike. Bringing MaaS to 3D printing services allows a single space to connect jobs to thousands of capable manufacturers with a large portfolio of capabilities.