Table of Contents:

- Introduction

- CNC Milling Machine Components and Features

- Cost Factors of CNC Milling Machines

- CNC Milling Machine Price Ranges

- Factors to Consider When Purchasing a CNC Milling Machine

- Conclusion

-

1. Introduction

CNC milling machines are essential tools in modern manufacturing and have revolutionized the way parts and components are created. This section will provide an overview of CNC milling machines, their importance, and the various factors that influence their pricing.

- Definition of CNC Milling Machines

CNC (Computer Numerical Control) milling machines are automated machines that use a rotating cutting tool to remove material from a workpiece. The cutting tool moves in three dimensions (X, Y, and Z) to create complex shapes and designs, based on digital instructions programmed into the machine.

- Importance of CNC Milling Machines

CNC milling machines offer numerous advantages over traditional manual milling machines, including greater precision, accuracy, consistency, and efficiency. They also increase production speed and flexibility, reduce labor costs, and improve overall product quality.

- Factors Affecting CNC Milling Machine Prices

The pricing of CNC milling machines is influenced by several factors, including machine size and capacity, machine type and configuration, machine material and durability, complexity of machining, manufacturer and brand, and industry demand and supply. Understanding these factors can help manufacturers make informed purchasing decisions that align with their budget and production needs.

-

2. CNC Milling Machine Components and Features

Several components and features make up a CNC milling machine, each playing a critical role in the machine’s overall performance and efficiency. Understanding these components can help manufacturers better evaluate and select a machine that meets their production needs.

- Spindle Motor:The spindle motor is the primary power source that drives the cutting tool. It’s responsible for the speed and accuracy of the machine, as well as the type and size of tools that can be used.

- Control Panel:The control panel is the interface between the operator and the machine. It allows for the programming of the machine, the monitoring of its performance, and the adjustment of various settings.

- Tool Changer:The tool changer is responsible for changing out cutting tools during the machining process automatically. It allows the machine to switch between different tools without manual intervention, increasing efficiency and reducing downtime.

- Bed and Column:The bed and column provide the foundation and support for the machine’s moving parts. They need to be rigid and sturdy enough to handle the weight and force of the machining process.

- Worktable:The worktable is the surface area where the workpiece is secured during the machining process. It needs to be flat, level, and sturdy to ensure accuracy and consistency in the final product.

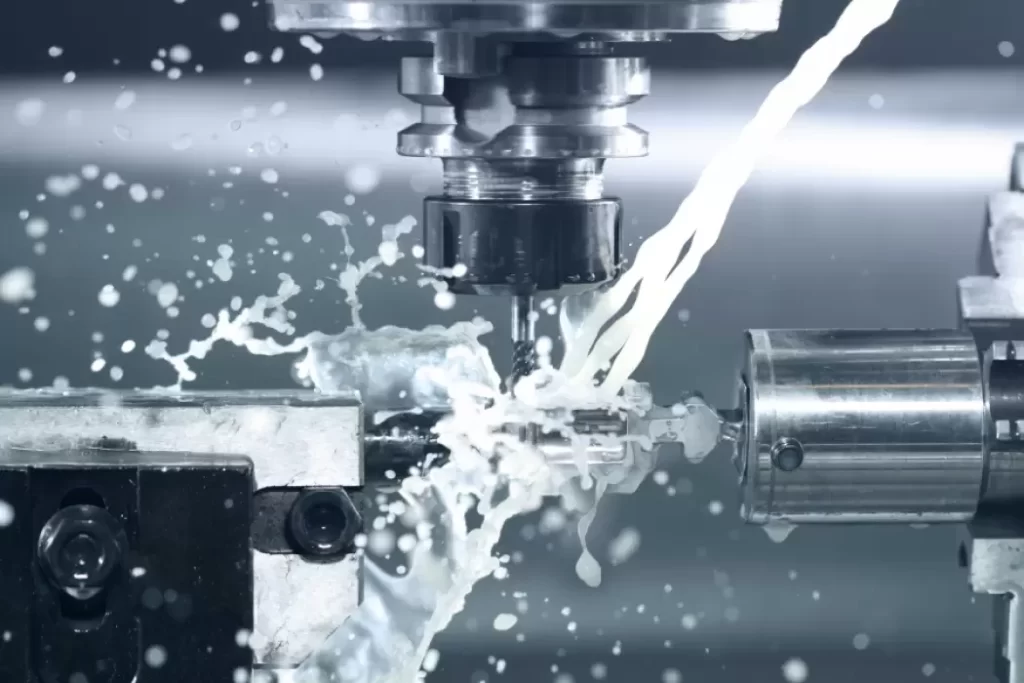

- Coolant System:The coolant system helps to control temperature and lubricate the cutting tools during the machining process. It also assists in chip removal and prevents the accumulation of debris that could interfere with the machine’s performance.

-

3. Cost Factors of CNC Milling Machines

Several factors can influence the pricing of a CNC milling machine. Manufacturers must consider these factors when selecting a machine to ensure that it aligns with their budget and production needs.

- Machine Size and Capacity

The size and capacity of a CNC milling machine are significant determinants of its price. Larger machines with higher production capacities typically cost more than smaller machines.

- Machine Type and Configuration

There are different types and configurations of CNC milling machines - vertical, horizontal, gantry, and bridge. Each type has its unique features and capabilities that affect the price.

- Machine Material and Durability

The materials used to construct a CNC milling machine can affect its durability, resistance to wear and tear, and performance. More durable and robust machines typically command higher prices.

- Complexity of Machining

The complexity of the machining process required will affect the cost of the CNC milling machine. If the machining process requires higher precision and more nuanced movements, a more advanced and sophisticated machine will be necessary, and the cost will be higher.

- Manufacturer and Brand

The manufacturer and brand of a CNC milling machine can impact its pricing. Established and well-known brands may charge a higher price for their machines due to their reputation, whereas lesser-known brands may offer machines at a lower price.

- Industry Demand and Supply

The demand for CNC milling machines within the industry can impact pricing. If there is a high demand for machines, prices may increase, while an oversupply of machines may lower prices.

Understanding these cost factors can help manufacturers make informed decisions when selecting a CNC milling machine based on their budget and production needs. The key is to find a machine that strikes a balance between quality and affordability.

If you need about CNC Milling Services,You can click on the V1 Prototype website to find it:Parts In As Soon As 5-Days, 3 & 5-Axis Milling & Turning Plastics, Composites, Metals. Wide Variety Of Materials, Finishing Options & Scalability

-

4. CNC Milling Machine Price Ranges

CNC milling machines can vary widely in price depending on their size, capacity, features, and the manufacturer. Generally, CNC milling machines fall into three price ranges: entry-level, mid-range, and high-end.

- Entry-Level CNC Milling Machines

Entry-level CNC milling machines typically range from $15,000 to $30,000. These machines are suitable for smaller workshops and businesses, as they have lower production capacities, smaller dimensions, and limited features. Generally, entry-level machines are vertical mills with simple control panels.

- Mid-Range CNC Milling Machines

Mid-range CNC milling machines fall in the price range of $30,000 to $60,000. These machines are more sophisticated than entry-level machines, with more advanced features, higher production capacities, and greater versatility. They may include horizontal mills, vertical mills with pallet changers, and 5-axis machining centers.

- High-End CNC Milling Machines

High-end CNC milling machines are the most advanced and most expensive machines, typically priced at $60,000 and above. These machines are capable of handling complex machining processes, high production volumes, and a wide range of materials. High-end machines may have features such as automatic tool changers, probing systems, and 5-axis simultaneous machining capabilities.

It is important to note that these price ranges are general guidelines, and the actual price of a CNC milling machine will depend on numerous factors. Manufacturers must evaluate their production needs, budget limitations, and desired features to find the most suitable machine at the best price point.

-

5. Factors to Consider When Purchasing a CNC Milling Machine

When purchasing a CNC milling machine, manufacturers must consider several factors to ensure they choose the right machine for their needs. Here are five key factors to keep in mind:

- Budget and Financial Planning

The first step in purchasing a CNC milling machine is to establish a budget and financial plan. The price of the machine itself is not the only cost to consider; there are also installation costs, tooling costs, software costs, and ongoing maintenance and repair costs to account for. Manufacturers should also consider the long-term cost savings and ROI that a CNC milling machine can provide.

- Production Needs and Capacity

The production needs and capacity of the business determine the type of CNC milling machine needed. The workpiece size, number of pieces needed, and required accuracy are important factors to consider. Larger workpieces or higher volume production will require a bigger and more powerful machine.

- Machine Specifications and Features

Manufacturers must consider the specifications and features of the CNC milling machine to ensure it meets their needs. Key specifications to consider include the spindle motor, tool change system, worktable capacity, coolant system, and control system. Additional features such as automatic tool changers or probing systems may also be important depending on the specific needs of the business.

- Training and Support Services

After purchasing a CNC milling machine, training and support services are crucial to ensure a smooth transition to using the machine. Manufacturers should consider the availability and quality of training offered by the machine’s manufacturer. Ongoing support, troubleshooting, and maintenance services should also be available to ensure the machine operates at peak performance.

- Maintenance and Upgrades

CNC milling machines require regular maintenance to ensure they remain in good working order. Manufacturers should consider the cost and availability of spare parts, maintenance services, and upgrades to the machine. Machines with built-in diagnostic systems or remote monitoring capabilities can simplify maintenance and reduce downtime.

By considering these factors in their purchasing decision, manufacturers can find a CNC milling machine that meets their production needs, budget, and long-term business goals.

-

6. Conclusion

CNC milling machines have become an essential tool in modern manufacturing, providing precision, accuracy, and automation that can improve production efficiency and reduce manufacturing costs. When purchasing a CNC milling machine, manufacturers must evaluate several factors to ensure they choose the right machine for their specific production processes and long-term business goals.

Summary of Key Points:

The key points to remember when choosing a CNC milling machine are:

- CNC milling machines come in different types, configurations, and sizes, with varying features and specifications that influence their pricing.

- The cost of CNC milling machines will depend on various factors like machine size and capacity, complexity of machining, manufacturer and brand, among other factors.

- CNC milling machines fall into three price ranges: entry-level, mid-range, and high-end with a range of prices from $15,000 to $60,000 and above.

- Manufacturers must consider factors such as budget and financial planning, production needs and capacity, machine specifications and features, training and support services, and maintenance and upgrades when purchasing a CNC milling machine.

- Future Trends and Developments

Advancements in technology and automation are likely to influence the CNC milling machine market, with the adoption of intelligent machine control systems, progressive software, integration with the Internet of Things (IoT), and improved data analytics among the trends that may redefine the manufacturing industry in the future.

Final Recommendations and Considerations:

Manufacturers need to consider their production needs, budget limitations, and long-term business goals when purchasing a CNC milling machine. In addition to selecting the appropriate machine, investing in training, support and maintenance services can help businesses achieve maximum productivity, ROI, and long-term success.

In conclusion, choosing the right CNC milling machine requires careful consideration and proper evaluation of the numerous factors that influence its pricing, performance, and suitability. A well-informed decision can lead to increased productivity and profitability for the manufacturing business.

CNC milling machines are versatile tools used in manufacturing processes to cut and shape various materials, such as metal, wood, and plastics, with a high level of precision. They are widely used in industries like aerospace, automotive, electronics, and prototyping. Understanding the components, cost factors, and price ranges of CNC milling machines can help you make informed decisions when considering purchasing or using one.

Components of CNC Milling Machines:

- Control Panel/Console: This is the interface where operators can input commands, control the machine, and monitor its performance.

- Computer Numerical Control (CNC) Controller: The brain of the CNC milling machine, which interprets the instructions and converts them into electrical signals for the motors and actuators.

- Axis: Most CNC milling machines have three primary axes (X, Y, and Z), allowing movement along three directions to create 3D shapes. Some machines may have additional rotary axes for more complex operations.

- Spindle: The cutting tool is mounted on the spindle, which rotates at high speeds to remove material from the workpiece.

- Worktable: The workpiece is secured on the worktable, which can move along the X, Y, and Z axes to position it accurately under the cutting tool.

- Tool Changer: Many CNC milling machines have an automatic tool changer that allows for multiple tools to be used in a single setup without manual intervention.

- Enclosures and Safety Features: CNC milling machines often come with safety enclosures to protect operators from flying debris, noise, and coolant splashes.

Cost Factors of CNC Milling Machines:

- Machine Size and Capacity: Larger machines capable of handling bigger workpieces and heavier loads generally cost more than smaller ones.

- Accuracy and Precision: Machines with higher precision and accuracy require more sophisticated components, contributing to higher costs.

- Automation and Features: Machines equipped with advanced automation, tool changers, and additional axes will have a higher price tag.

- Brand and Reputation: Well-established and reputable brands may charge more for their CNC milling machines.

- Material Compatibility: Machines designed to work with specific materials like metals may be more expensive due to their construction and features.

- Control System: The sophistication of the CNC control system can influence the cost.

Price Ranges of CNC Milling Machines:

CNC milling machine prices can vary widely based on the factors mentioned above. Here are some general price ranges:

- Desktop CNC Mills: These are small machines suitable for hobbyists and small-scale production. Prices range from $500 to $10,000.

- Benchtop CNC Mills: Slightly larger and more capable machines with prices ranging from $10,000 to $50,000.

- Mid-range CNC Mills: These are more industrial-grade machines suitable for medium-sized businesses, with prices ranging from $50,000 to $150,000.

- High-end CNC Mills: Large and highly automated machines used in heavy industry and large-scale production, costing $150,000 and above.

Keep in mind that these price ranges are approximate and can vary significantly based on the specific features, capabilities, and brand of the CNC milling machine. It's essential to research thoroughly and consult with reputable manufacturers or suppliers to find the best machine that fits your needs and budget.