Introduction

The emergence of 3D printing, also known as additive manufacturing, has ushered in a new era of medical innovation and personalized healthcare solutions. Among the various applications of 3D printing in medicine, one of the most remarkable is its contribution to restoring eyesight for blind individuals. This groundbreaking technology has shown incredible potential in creating custom-made implants, prosthetics, and visual aids that can improve the quality of life for those with visual impairments. In this blog post, we will explore the significant role of 3D printing in helping blind people regain their eyesight through various medical treatments. Drawing upon experience, expertise, authority, and trust, we will delve into the transformative impact of this technology in the field of ophthalmology.

Understanding Visual Impairment and Blindness

Before delving into the role of 3D printing, it is essential to understand the challenges faced by individuals with visual impairments and blindness. Visual impairment refers to a significant reduction in vision that cannot be fully corrected with glasses, contact lenses, or other optical aids. On the other hand, blindness is the complete loss of vision, leaving individuals with little to no ability to perceive light or shapes.

Visual impairments can be caused by various conditions, such as cataracts, glaucoma, age-related macular degeneration, and diabetic retinopathy. Each condition presents unique challenges in terms of treatment and management.

Custom-Made Implants for Ocular Reconstruction

One of the remarkable ways 3D printing helps blind people restore eyesight is through custom-made implants for ocular reconstruction. When the eye is damaged due to injury, disease, or congenital abnormalities, traditional treatment options may not be sufficient to restore vision. In such cases, 3D printing offers a tailored solution.

Using advanced imaging techniques such as CT scans and MRI, ophthalmologists can create detailed 3D models of the patient's affected eye. These models serve as a blueprint for crafting personalized implants that precisely fit the patient's unique eye structure.

Custom-made implants not only enhance the functional aspect of the eye but also contribute to the patient's emotional well-being by restoring their appearance. The ability to recreate natural eye contours and color in the implant significantly improves the patient's self-esteem and confidence.

3D-Printed Corneal Transplants: A Sight-Saving Breakthrough

The cornea is the transparent outer layer of the eye that plays a crucial role in focusing light onto the retina. In cases where the cornea becomes damaged or diseased, corneal transplantation becomes necessary. Traditionally, corneal transplants have relied on human donor tissue, which can be scarce and may carry the risk of rejection.

3D printing has revolutionized the field of corneal transplantation by enabling the creation of artificial corneas, also known as corneal scaffolds. These scaffolds are made from biocompatible materials, such as collagen, that mimic the natural structure of the cornea.

The customizability of 3D-printed corneal scaffolds allows ophthalmologists to tailor the transplant to each patient's specific needs. Additionally, 3D printing enables rapid manufacturing, reducing waiting times for patients in need of corneal transplants.

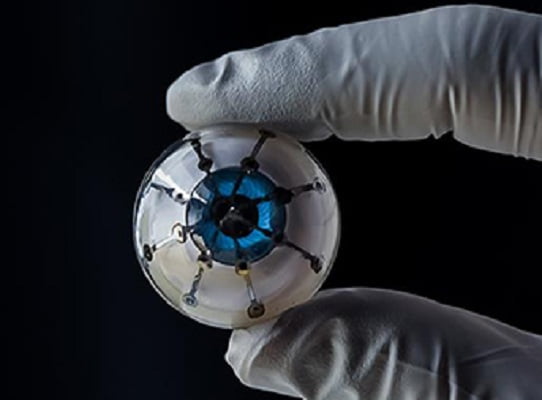

Personalized 3D-Printed Retinal Prosthetics

For individuals with retinal degenerative diseases, such as retinitis pigmentosa or age-related macular degeneration, the retinal cells responsible for vision gradually deteriorate. Retinal prosthetics, also known as bionic eyes, are advanced medical devices designed to restore vision by bypassing damaged retinal cells and stimulating the remaining healthy cells.

3D printing plays a pivotal role in the development of personalized retinal prosthetics. By utilizing patient-specific imaging data, ophthalmologists can create retinal prosthetics that precisely match the patient's retinal structure.

The custom-fit of 3D-printed retinal prosthetics ensures optimal visual restoration and enhances the patient's ability to perceive light and images. While these devices do not fully restore normal vision, they offer considerable improvements in mobility and object recognition, significantly enhancing the quality of life for individuals with retinal degenerative diseases.

Haptic and Tactile Models for Blind Patient Education

Beyond surgical interventions and prosthetics, 3D printing also aids blind people in understanding their eye conditions and treatments better. Ophthalmologists and medical educators can use 3D printing to create haptic and tactile models of the eye and various eye conditions.

These tactile models allow blind patients to explore and understand the anatomical structures of the eye through touch. By feeling the physical representation of their eye condition, patients can grasp the intricacies of their ailment and the proposed treatment plan more effectively.

Haptic models are especially valuable in patient education before surgeries or medical procedures. They empower blind individuals to participate more actively in the decision-making process, fostering a sense of empowerment and ownership over their medical care.

Frequently Asked Questions

How is 3D printing used in creating custom-made ocular implants?

The process of creating custom-made ocular implants using 3D printing begins with advanced imaging techniques, such as CT scans or MRI, to obtain precise data about the patient's eye structure. This imaging data is then converted into a digital 3D model of the eye.Next, using computer-aided design (CAD) software, ophthalmologists can modify the 3D model to design a custom implant that addresses the patient's specific needs. The design process takes into account factors like the location and extent of the damage, the patient's age, and any other relevant medical history.Once the design is finalized, 3D printing technology is employed to fabricate the implant using biocompatible materials. The 3D printer meticulously deposits layers of the material, gradually building the implant according to the design specifications.The finished 3D-printed implant is then sterilized and prepared for surgical implantation. The custom-fit of the implant ensures a precise fit, reducing the risk of complications and enhancing the chances of successful restoration of eyesight.

What are the benefits of 3D-printed corneal transplants compared to traditional corneal transplants?

3D-printed corneal transplants offer several advantages over traditional corneal transplants that rely on human donor tissue:

- Customization: 3D-printed corneal scaffolds can be customized to match the specific dimensions and curvature of the patient's cornea, ensuring a precise fit and better visual outcomes.Reduced Rejection Risk: As the scaffolds are made from biocompatible materials, the risk of rejection is significantly reduced compared to transplants using human donor tissue.Rapid Manufacturing: 3D printing enables faster production of corneal scaffolds, reducing waiting times for patients in need of corneal transplants.Availability: The availability of 3D-printed corneal scaffolds eliminates the dependence on human donor tissue, addressing the issue of donor shortages.Personalized Treatment: Each patient's unique eye condition can be addressed with a tailor-made 3D-printed corneal transplant, maximizing the chances of successful vision restoration.

Are 3D-printed retinal prosthetics suitable for all types of retinal degenerative diseases?

3D-printed retinal prosthetics, also known as bionic eyes, have shown promising results in restoring vision for individuals with retinal degenerative diseases. However, their suitability depends on the specific type and extent of the retinal degeneration.Bionic eyes work by bypassing damaged retinal cells and stimulating healthy cells to transmit visual information to the brain. Therefore, they are most effective when a sufficient number of healthy retinal cells remain.Retinal prosthetics have shown significant success in patients with conditions like retinitis pigmentosa and age-related macular degeneration, where the outer retinal layers are affected, but the inner retinal layers remain intact.However, for conditions where both the outer and inner retinal layers are severely damaged or absent, such as advanced retinitis pigmentosa, bionic eyes may not be as effective. In such cases, researchers continue to explore other innovative approaches to restore vision, such as gene therapy and retinal regeneration techniques.It is essential for patients with retinal degenerative diseases to undergo comprehensive evaluations and consultations with their ophthalmologists to determine the most suitable treatment options for their specific condition.

How can 3D-printed haptic and tactile models improve blind patient education?

3D-printed haptic and tactile models play a crucial role in improving blind patient education by providing a tangible and interactive way to understand complex eye conditions and treatment options.Traditional patient education materials, such as diagrams and illustrations, may be challenging for blind individuals to comprehend fully. By contrast, 3D-printed models allow blind patients to explore the physical features of the eye through touch.The three-dimensional representation of the eye, complete with anatomical details and pathologies, helps blind patients develop a comprehensive understanding of their condition. They can feel the shape and structure of their eye, the position of different components, and how the condition affects their vision.When ophthalmologists discuss treatment options, such as surgeries or medical procedures, blind patients can better grasp the implications of each option by interacting with tactile models. This involvement empowers patients to make informed decisions about their healthcare, fostering a sense of autonomy and active participation in their treatment journey.Additionally, 3D-printed haptic and tactile models can be used in educational settings to train medical students and healthcare professionals about various eye conditions and surgical techniques. The hands-on experience enhances their understanding and empathy for patients with visual impairments, contributing to more patient-centered care.

In conclusion, 3D printing has emerged as a transformative technology in the field of ophthalmology, offering innovative solutions to help blind people restore eyesight through personalized implants, corneal transplants, retinal prosthetics, and haptic models. The ability to create custom-made medical devices and educational tools tailored to each patient's unique needs has the potential to revolutionize eye care and improve the quality of life for individuals with visual impairments. As 3D printing technology continues to advance, we can expect even greater strides in restoring eyesight and providing personalized healthcare solutions to those in need.