What is 3D Printing?

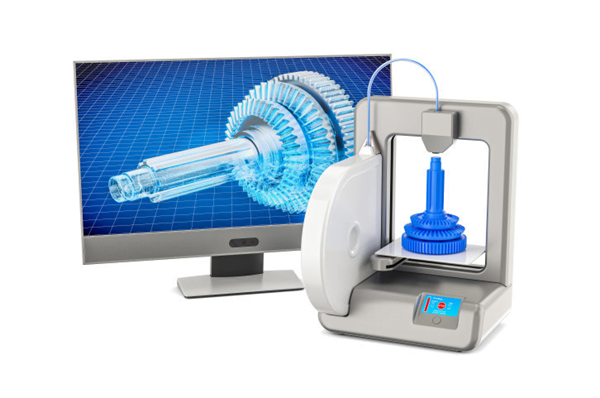

3D printing, also known as additive manufacturing, is a revolutionary technology that allows the creation of three-dimensional objects layer by layer, based on digital design data. Unlike traditional subtractive manufacturing methods that involve cutting and shaping materials, 3D printing adds material to build up the final object, making it a highly efficient and versatile manufacturing process.

How Does 3D Printing Work?

The 3D printing process typically involves the following steps:

- Designing the 3D Model: The process begins with the creation of a digital 3D model using computer-aided design (CAD) software. The design is then sliced into thin horizontal layers using slicing software, which generates instructions for the 3D printer.

- Printing the Object: The 3D printer interprets the sliced design and starts the printing process. The printer nozzle or print head deposits the material, layer by layer, following the instructions from the slicing software. As each layer is completed, the build platform moves down (or the print head moves up) to allow for the next layer to be added on top of the previous one.

- Solidifying the Material: Depending on the 3D printing technology, the material is solidified through various methods. For example, in Fused Deposition Modeling (FDM), thermoplastic filaments are melted and deposited, while in Stereolithography (SLA), photopolymer resins are cured using UV light.

- Finishing and Post-Processing: Once the printing is complete, the 3D printed object may require post-processing, such as cleaning, removal of support structures, and surface finishing to achieve the desired appearance and functionality.

Common 3D Printing Materials

Numerous materials are used in 3D printing, each catering to specific applications and requirements. Some of the most common 3D printing materials include:

- Polylactic Acid (PLA): PLA is a biodegradable and easy-to-print material made from renewable resources like cornstarch or sugarcane. It is widely used for prototypes, hobby projects, and consumer goods due to its low toxicity and ease of use.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a durable and impact-resistant thermoplastic commonly used in Fused Deposition Modeling (FDM) 3D printing. It is suitable for functional prototypes, automotive parts, and household items.

- Polyethylene Terephthalate Glycol (PETG): PETG is a variant of PET and offers enhanced toughness and clarity. It is used for water bottles, food containers, and medical applications.

- Nylon (Polyamide): Nylon is known for its strength, flexibility, and resistance to abrasion. It finds applications in functional prototypes, mechanical parts, and engineering components.

- Polycarbonate (PC): PC is a tough, impact-resistant material with high-temperature resistance. It is used in aerospace, automotive, and engineering applications.

- Photopolymer Resins: Photopolymer resins are commonly used in Stereolithography (SLA) and Digital Light Processing (DLP) 3D printing. They come in various formulations, including standard, tough, flexible, and castable resins, catering to a wide range of applications from prototyping to dental and jewelry production.

- Metal Powders: Metal 3D printing, also known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), uses metal powders like stainless steel, titanium, aluminum, and cobalt-chrome to produce end-use parts and functional prototypes for aerospace, medical, and automotive industries.

- Wood-Filled Filaments: Wood-filled filaments combine PLA with wood fibers, offering a natural wood-like appearance and texture. They are used in decorative objects, architectural models, and artistic creations.

Conclusion

3D printing is a transformative technology that has revolutionized the way we design, prototype, and manufacture objects. With its ability to utilize a wide range of materials, 3D printing caters to various industries and applications, from rapid prototyping to end-use part production. As the technology continues to advance, we can expect even more innovative materials and techniques, further expanding the possibilities and applications of 3D printing in the future.

Definition: 3D printing simply means that the 3D model in the computer is printed out in layers by 3D printing equipment, and the layers are superimposed into a physical product.

Process: Have a physical object-3D scanning-3D printing-post-processing (polishing, coloring, plating, silk-screening, etc.)

Have picture or design draft-3D modeling-3D printing-post-processing (polishing, coloring, plating, silkscreening, etc.)

The most difficult point here is the 3D modeling, most of our designers have a certain understanding of graphic design, but not much understanding of 3D modeling, which is also a shackle limiting the development of 3D printing, complex design 3D modeling is not too cheap.

3D printing materials: 3D printing materials up to more than 50 kinds of materials, corresponding to the different needs of everyone, commonly used materials are as follows.

PLA material: polylactic acid biodegradable environmental protection material, the cheapest material, color optional, general accuracy, the surface has layer pattern, suitable for the budget is not high, the model accuracy is not high, the strength of a slightly demanding group. Currently on the market there is a direct sale of finished 3D printed PLA vase, the aesthetics are not bad.

Resin material: polymer resin, resin can also be subdivided into white ordinary resin, yellow toughness resin, high temperature resin, transparent resin, is the most used material in 3D printing material, the later can be finely polished, coloring, plating, screen printing can be done; suitable for display model, hand model, hand board proofing, crafts, jewelry, etc., white ordinary resin is inexpensive; the disadvantage is that the resin strength is poor. Not very strong, can not fall.

Nylon material: nylon has white nylon, HP black nylon, high strength, toughness, suitable for industrial parts, is a particularly suitable material for researchers and developers. In addition, white nylon in foreign clothing design, jewelry design applications are also quite extensive

Metal materials: metal gold, silver and copper, do jewelry with, there are stainless steel aluminum alloy to do performance testing with is also very wide.

Today first say these, in fact, the traditional process is to mold to do the product, 3D printing is a direct 3D model to print out the finished product, and do not need to do the mold, so you have any ideas welcome and I communicate