This article explores the differences between subtractive and additive manufacturing, two of the most common manufacturing processes. Learn about the technology, materials, and applications of both subtractive and additive manufacturing, and how they can be used in different industries and applications.

Table of Contents:

I. Introduction

- Definition of subtractive and additive manufacturing

- Overview of subtractive and additive manufacturing processes

II. Subtractive Manufacturing Technology

- Types of subtractive manufacturing technology

- Components of subtractive manufacturing machines

III. Additive Manufacturing Technology

- Types of additive manufacturing technology

- Components of additive manufacturing machines

IV. Materials Used in Subtractive and Additive Manufacturing

- Types of materials used

- Properties of materials

V. Applications of Subtractive and Additive Manufacturing

- Industries that use subtractive and additive manufacturing

- Examples of subtractive and additive manufacturing applications

VI. Advantages and Limitations of Subtractive and Additive Manufacturing

- Advantages of subtractive and additive manufacturing

- Limitations of subtractive and additive manufacturing

VII. Comparison of Subtractive and Additive Manufacturing

- Differences between subtractive and additive manufacturing

- Choosing the right process for your application

VIII. Conclusion

- Future of subtractive and additive manufacturing

I. Introduction

Subtractive and additive manufacturing are two of the most common manufacturing processes used in various industries. Subtractive manufacturing involves removing material from a larger block of material to create a finished product, while additive manufacturing involves building up layers of material to create a 3D object. In this article, we will explore the technology, materials, and applications of both subtractive and additive manufacturing.

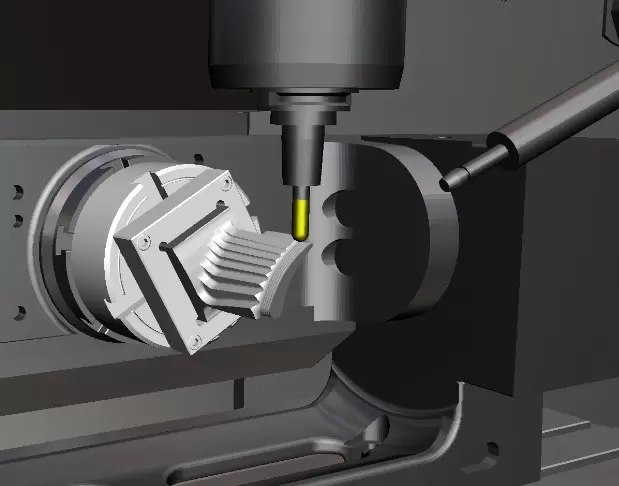

II. Subtractive Manufacturing Technology

Subtractive manufacturing involves various technology, such as milling, grinding, and lathing. These machines remove material from a larger block of material to create a finished product. They operate using Computer-Aided Design (CAD) files to guide the manufacturing process.

III. Additive Manufacturing Technology

Additive manufacturing involves several printing technologies like Material Jetting, Powder Bed Fusion, Directed Energy Deposition, and Binder Jetting, among others. The process involves depositing material layer by layer to create a finished product. They operate using 3D modelling software and G-code to guide the manufacturing process.

IV. Materials Used in Subtractive and Additive Manufacturing

Subtractive manufacturing processes can use a wide range of materials, including metals, plastics, ceramics, and wood. Additive manufacturing processes also use a range of materials like polycarbonate, PLA or ABS plastic, metals like aluminum, various bioplastics, and others. The choice of material will depend on the requirements of the final product, such as its strength, flexibility, and temperature resistance.

V. Applications of Subtractive and Additive Manufacturing

Subtractive manufacturing is commonly used in industries like aerospace, automotive, and medical to create large and complex parts. Additive manufacturing processes are used across various industries from rapid prototyping and food technologies to building custom prosthetics for patients.

VI. Advantages and Limitations of Subtractive and Additive Manufacturing

Subtractive manufacturing offers high precision and cost-effective manufacturing but can be more time-consuming and produce up to 50 percent more waste than additive processes. Additive manufacturing technologies offer incredible design flexibility, speed, and the ability to affordably produce complex geometries.

VII. Comparison of Subtractive and Additive Manufacturing

When choosing between additive and subtractive manufacturing processes, key consideration factors include materials availability, cost, final use, the scale of production, speed of production, and what kind of technology is already available.

VIII. Conclusion

Both subtractive and additive manufacturing offer various advantages and limitations, so choosing the right technology will depend on the final use, material requirements, and production capabilities. As technology improves, advancements in both subtractive and additive manufacturing will continue to push the boundaries of what is possible for manufacturing process optimization and even further drive productivity.

Manufacturing processes are diverse, and two prominent methods are subtractive manufacturing and additive manufacturing. Both approaches have distinct characteristics, advantages, and applications. This article aims to explain the differences between subtractive and additive manufacturing and explore the unique benefits they offer to various industries.

- Subtractive Manufacturing:

Subtractive manufacturing, also known as traditional or machining manufacturing, involves removing material from a solid block or workpiece to achieve the desired shape. This is achieved through cutting, drilling, milling, grinding, or other machining techniques. The process begins with a larger block of material, and the excess material is removed until the final product is obtained.

Advantages of Subtractive Manufacturing:

- Suitable for various materials, including metals, plastics, wood, and composites.

- Produces high-precision and accurate parts with tight tolerances.

- Ideal for producing large-scale, mass-produced components.

- Excellent surface finish and quality can be achieved.

Applications of Subtractive Manufacturing:

- Automotive: Production of engine components, gears, and transmission parts.

- Aerospace: Manufacturing aircraft components, turbine blades, and structural parts.

- Consumer Goods: Creating metal or plastic parts for appliances and electronics.

- Additive Manufacturing:

Additive manufacturing, commonly known as 3D printing, is a process of building three-dimensional objects layer by layer from a digital 3D model. Instead of removing material like in subtractive manufacturing, additive manufacturing adds material only where it is needed, minimizing waste and enabling complex geometries.

Advantages of Additive Manufacturing:

- Enables rapid prototyping and reduced time-to-market for new products.

- Freedom to create intricate and complex designs, including internal structures and hollow parts.

- Customization and personalization of products for individual needs.

- Minimal material waste, making it more sustainable and cost-effective for small-batch production.

Applications of Additive Manufacturing:

- Medical: Customized prosthetics, patient-specific implants, and surgical guides.

- Aerospace: Lightweight components, complex fuel nozzles, and aircraft interior parts.

- Automotive: Prototyping, custom car parts, and tooling for production.

- Combining Both Methods:

In some cases, manufacturers employ both subtractive and additive manufacturing processes to take advantage of their respective strengths. This combination is known as hybrid manufacturing. For example, additive manufacturing can be used to create intricate features or cooling channels within a workpiece, which is then finished using subtractive methods to achieve precise dimensions and surface finish.