I. Introduction

A. Explanation of OSAHS

Obstructive Sleep Apnea and Hypopnea Syndrome (OSAHS) is a prevalent sleep disorder characterized by recurrent episodes of partial or complete upper airway obstruction during sleep. This condition not only results in disrupted sleep patterns but also contributes to a myriad of health issues such as hypertension, cardiovascular diseases, and cognitive impairments. OSAHS poses a significant public health concern, affecting millions globally.

B. Importance of Personalized Treatment

The one-size-fits-all approach in healthcare is evolving, and personalized treatment strategies are gaining prominence. Tailoring interventions to the unique characteristics of each patient is crucial, especially in the case of OSAHS. Personalized treatment not only addresses the specific needs of individuals but also enhances treatment efficacy and patient outcomes. This individualized approach considers factors like anatomical variations, severity of symptoms, and patient preferences.

II. Digital 3D Printing Technology: An Overview

Digital 3D printing, commonly known as additive manufacturing, has emerged as a transformative technology, reshaping the way we create objects in various industries. This article provides an overview of the basic principles of 3D printing, highlighting its evolution and advancements over the years.

Basic Principles of 3D Printing

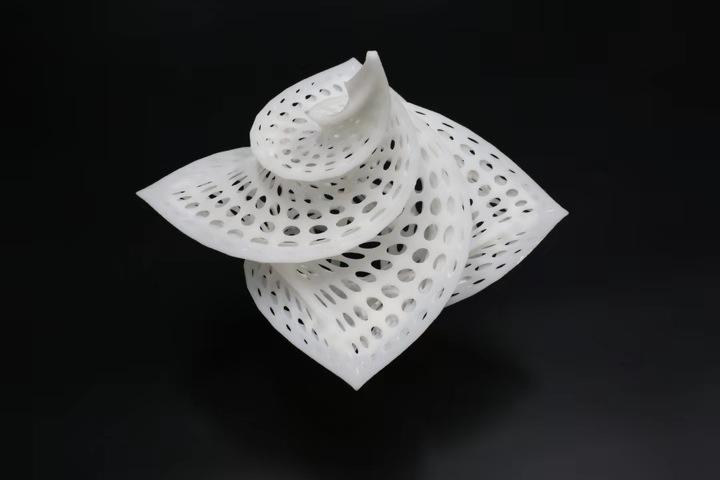

At its core, digital 3D printing involves the layer-by-layer creation of three-dimensional objects from digital models. This innovative process utilizes a range of materials, including polymers, metals, and ceramics, to construct intricate structures with unparalleled precision. The journey from a digital model to a tangible object begins with the slicing of the digital design into thin layers. The 3D printer then systematically adds material layer by layer, meticulously bringing the digital concept to life until the final object is produced.

The versatility of 3D printing extends to various industries, allowing for the creation of prototypes, functional components, and customized products. The ability to work with diverse materials and produce complex geometries has made it a preferred method in manufacturing and design.

Evolution and Advancements in the Field

The roots of 3D printing trace back to the 1980s, marking its inception as a groundbreaking technology. Since then, the field has witnessed remarkable advancements, expanding its applications across numerous sectors. Initially used for prototyping, 3D printing has evolved into a sophisticated tool for manufacturing functional components with efficiency and precision.

One of the most significant areas of growth is observed in the healthcare industry. The evolution of 3D printing technology has revolutionized medical practices by enabling the production of customized medical devices, implants, and prosthetics. This has opened new frontiers for personalized patient care, as healthcare professionals can tailor solutions to meet the unique needs of individual patients.

Customization and precision are key advantages offered by 3D printing in healthcare. From patient-specific implants that perfectly match an individual's anatomy to prosthetics designed for optimal comfort and functionality, this technology has proven invaluable in improving the quality of life for many.

Beyond healthcare, 3D printing has found applications in aerospace, automotive, architecture, and consumer goods industries. It has become an integral part of rapid prototyping and small-scale production, allowing for cost-effective and efficient manufacturing processes.

III. Application in OSAHS Treatment

A. Customized Oral Appliances

Benefits of Personalized Design

Digital 3D printing has revolutionized the fabrication of oral appliances for OSAHS treatment. Customization allows the creation of devices tailored to the patient's unique anatomy, ensuring optimal comfort and effectiveness. These personalized appliances provide better fit, reducing the risk of discomfort or non-compliance. Patients experience improved treatment outcomes due to the precision in addressing their specific needs.

Case Studies Showcasing Successful Outcomes

Numerous case studies highlight the success of personalized oral appliances manufactured using 3D printing technology. Patients report increased compliance, reduced side effects, and improved quality of sleep. The ability to customize oral appliances based on individual anatomical variations contributes significantly to the overall effectiveness of OSAHS treatment.

B. Surgical Implants and Prosthetics

Precision and Accuracy in Implant Placement

In surgical interventions for OSAHS, such as maxillomandibular advancement procedures, 3D printing ensures precision in creating patient-specific implants. The ability to replicate the patient's anatomy allows surgeons to plan and execute procedures with unparalleled accuracy. This precision minimizes the risk of complications and enhances the overall success of the surgical intervention.

Impact on Patient Recovery and Quality of Life

The use of 3D-printed surgical implants and prosthetics in OSAHS treatment has a profound impact on patient recovery. Customized implants promote faster healing, reduce postoperative discomfort, and contribute to improved long-term outcomes. Patients experience enhanced quality of life as they recover more efficiently, allowing them to resume normal activities sooner.

IV. Advantages of Integrating Digital 3D Printing in OSAHS Treatment

Obstructive Sleep Apnea and Hypopnea Syndrome (OSAHS) pose significant challenges in terms of treatment due to the individualized nature of patients' needs. The integration of digital 3D printing technology in OSAHS treatment has emerged as a groundbreaking solution, offering numerous advantages that address key issues in device production, cost-effectiveness, and patient satisfaction.

A. Speed and Efficiency in Device Production

One of the primary benefits of adopting digital 3D printing in OSAHS treatment is the remarkable speed and efficiency in device production. Traditional manufacturing methods often involve time-consuming processes, resulting in delayed treatment for patients. In contrast, 3D printing allows for the rapid customization of oral appliances and surgical implants. The quick turnaround not only meets the immediate needs of OSAHS patients but also facilitates prompt adjustments to accommodate any changes in their condition.

B. Cost-Effectiveness for Both Patients and Healthcare Providers

Despite initial reservations about the costs associated with implementing 3D printing technology, its integration in OSAHS treatment proves to be a cost-effective approach in the long run. The investment in 3D printing pays off through reduced material wastage and streamlined production processes. This not only benefits patients by making personalized treatment more affordable but also proves advantageous for healthcare providers, enabling them to allocate resources more efficiently. Ultimately, the cost-effectiveness of 3D printing contributes to expanding accessibility to personalized OSAHS treatment.

C. Enhancing Patient Satisfaction and Adherence to Treatment

The tailored approach made possible by digital 3D printing significantly enhances patient satisfaction and adherence to OSAHS treatment regimens. Patients are more likely to comply with therapy when provided with personalized devices that cater to their individual preferences and comfort levels. The ability to customize oral appliances and surgical implants ensures a better fit, minimizing discomfort and maximizing effectiveness. As a result, improved adherence leads to better treatment outcomes and the long-term management of OSAHS.

V. Challenges and Future Prospects

A. Technical Limitations and Current Challenges

Despite its numerous advantages, digital 3D printing in OSAHS treatment faces technical limitations. The need for biocompatible materials suitable for 3D printing, as well as the resolution of printing processes, remains areas of ongoing research. Overcoming these technical challenges is crucial to expanding the scope and applicability of 3D printing in the field of sleep medicine.

B. Ethical Considerations and Regulatory Landscape

As with any innovative technology, ethical considerations and regulatory frameworks must evolve alongside the advancements in 3D printing for OSAHS treatment. Ensuring patient safety, privacy, and informed consent are paramount. Regulatory bodies need to establish guidelines that address the ethical implications of utilizing 3D printing in healthcare.

C. Potential Future Developments and Innovations in the Field

The future of digital 3D printing in OSAHS treatment holds exciting possibilities. Continued research may lead to the development of even more advanced materials, improved printing techniques, and enhanced software for precise modeling. Integration with artificial intelligence may further optimize treatment plans, making personalized care more accessible and effective.

In conclusion, the integration of digital 3D printing technology in OSAHS treatment signifies a paradigm shift towards personalized and efficient healthcare. As advancements continue, the synergy between technology and medicine holds the promise of transforming the landscape of sleep medicine, ultimately improving the lives of individuals affected by OSAHS.