Professional Rapid Prototyping Services

Plastic & Metal Batch Production

V1 Rapid Prototype helping people make parts and products in 2006. We offer in terms of quality and service and with the aim to become the fastest and most dependable in the world.

As our company and customer base has grown so has our range of services. We are now one of the only companies in the world to offer such a massive range of prototyping and bespoke low volume manufacturing solutions all under one roof. Our high tech rapid prototyping and production facilities include CNC milling, 3D printing (SLA and SLS), vacuum casting (cast urethanes), sheet metal and rapid tooling and injection molding as well as traditional model making and a range of finishing techniques.

leave a message

Contact

Contact us now to bring your idea into reality, our professional team will respond you in 24 hours after we get your email.

- Email: info@v-1.com

- Office Address: 2nd Floor, NO. 10 Lianhu Road, Changan Town, Dongguan City, Guangdong Province, China, 523850

- Factory Address: No.38, Hexing Road, Shatou, Changan Town, Dongguan City, Guangdong Province, China, 523850

Related Rapid Prototyping Services

Custom sheet metal fabrication is a manufacturing process that involves shaping and forming sheet metal into custom-designed parts and products.

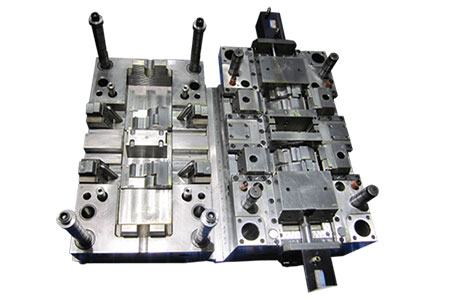

Mastering Injection Molding Tooling: Design, Production, Optimization, and Costs

ection molding tooling is a method widely used in the manufacturing industry to produce parts from thermoplastic materials.

Exploring the Sheet Additive Manufacturing Process: A Comprehensive Guide

Discover the innovative world of sheet additive manufacturing. This comprehensive guide explores the process, benefits, applications, and future prospects of this cutting-edge technology. Table of Contents: 1. Introduction In recent years, additive manufacturing has revolutionized the manufacturing industry by enabling the production of complex and customized parts with ease. One emerging technology within the additive manufacturing field is sheet additive manufacturing. This comprehensive guide aims to delve into the world of sheet additive manufacturing, exploring its process, benefits, applications, and future prospects. Join us as we embark on this exciting journey into the world of sheet additive manufacturing. 2. Understanding...

Die Casting Products: An Overview of Types, Materials, and Applications

Die casting is a metal casting process that involves injecting molten metal under high pressure into a mold cavity, forming the metal into the desired shape.

The technical basis of machining: production process and production type

Technology foundation The production process The process of machine production refers to the whole process of making products from raw materials (or semi-finished products). For machine production, it includes transportation and storage of raw materials, preparation of production, manufacturing of blanks, processing and heat treatment of parts, assembly and commissioning of products, painting and packaging, etc. The content of the production process is very extensive. Modern enterprises use the principles and methods of systems engineering to organize and guide production, and regard the production process as a production system with input and output. In the production process, usually change the...

Introduction Hot die casting is a highly efficient and widely used manufacturing process that allows for the production of intricate and complex metal parts with excellent dimensional accuracy. It has revolutionized the manufacturing industry, enabling the creation of a wide range of products that are vital for various sectors. In this extensive blog post, we will delve into the intricacies of hot die casting, exploring its method, applications, advantages, and the factors that contribute to its authority and trustworthiness as a preferred manufacturing technique. What is Hot Die Casting? Hot die casting, also known as high-pressure die casting, is a...