Blog Center

The Ultimate Guide to 3D Printing Service: Technology, Applications, and Future Trends

3D printing service refers to a digital fabrication process used to create three-dimensional objects. This technology involves the creation of physical models from digital blueprints or computer-aided design (CAD) models.

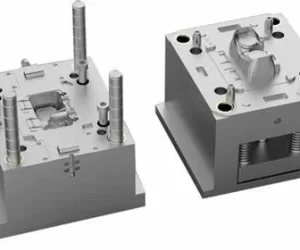

Applications Advantages for Design Injection Moulding Products

Table of Contents: Introduction: Injection moulding is a manufacturing process that is widely used in the production of a wide variety of products. This process involves the creation of complex shapes and designs by injecting molten material into a mould cavity, which is then allowed to cool and solidify. Injection...

The Importance of CNC Machining Near Me: Finding the Right Services for Your Business

In today's fast-paced manufacturing industry, companies are constantly seeking ways to improve efficiency and accuracy while reducing costs. One of the most effective methods for achieving these goals is through the use of CNC machining. Computer Numerical Control (CNC) machining is a manufacturing process that utilizes automated tools and machines...

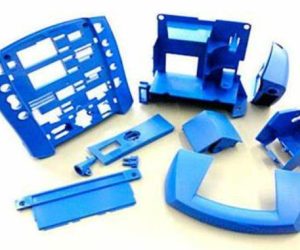

Plastic Injection Molding Services: A Comprehensive Guide

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. This process is used to create a variety of plastic products, from toys to medical devices to automotive parts. In this article, we'll provide a comprehensive guide to plastic injection molding services,...

A Comprehensive Guide to Plastic Gears: Types, Applications, and Benefits

Plastic gears are widely used in various industries for their lightweight, corrosion resistance, and low-cost manufacturing. In this comprehensive guide, we will explore the different types of plastic gears, their applications, and the benefits they offer. We will also discuss the manufacturing process and factors to consider when selecting plastic...

Plastic Injection Mold Machines: Types, Advantages, and Maintenance Tips

Plastic injection mold machines are widely used in the manufacturing industry for producing plastic parts and products. These machines use a process called injection molding to melt and inject plastic materials into molds, which are then cooled and solidified into the desired shape. In this article, we will discuss the...

Stainless Steel Sheet Metal: Properties, Uses, and Fabrication Techniques

Stainless steel sheet metal is a highly versatile material that is widely used in various industries, including construction, manufacturing, and engineering. Its unique properties make it ideal for applications that require high corrosion resistance, strength, and durability. In this article, we will discuss the properties, uses, and fabrication techniques of...

Copper Sheet Metal: Properties, Uses, and Fabrication Techniques

Copper sheet metal is a versatile and highly useful material that is widely used in various industries, including construction, manufacturing, and engineering. Its unique properties make it ideal for applications that require high thermal and electrical conductivity, corrosion resistance, and durability. In this article, we will discuss the properties, uses,...

Sheet Metal Fabrication Near Me: Finding the Best Services for Your Project

Sheet metal fabrication is an essential service for various industries, including construction, manufacturing, and engineering. From custom-made parts to large-scale production runs, sheet metal fabrication plays a crucial role in creating high-quality products. If you are in need of sheet metal fabrication services, you want to find a reliable and...

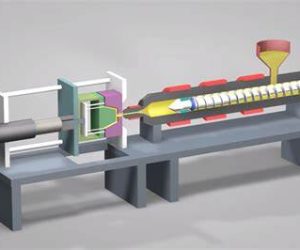

The Ins and Outs of Injection Molding Processing: A Comprehensive Guide

1> Introduction to Injection Molding Processing2>The Process of Injection Molding3>Design Considerations for Injection Molding4>Material Selection for Injection Molding5>Troubleshooting Injection Molding Issues6>Advantages and Disadvantages of Injection Molding7>Conclusion Introduction to Injection Molding Processing: Injection molding is a manufacturing process used to produce complex plastic parts with high precision and accuracy. The process...

A Comprehensive Guide to Aluminum Sheet Metal: Properties, Uses, and Manufacturing Process

1> Introduction Aluminum Sheet Metal2> Properties of Aluminum Sheet Metal3> Manufacturing Process of Aluminum Sheet Metal4> Uses of Aluminum Sheet Metal5> Advantages of Aluminum Sheet Metal6> Conclusion of Aluminum Sheet Metal Introduction Aluminum is a versatile and widely used metal in the manufacturing industry. It is known for its lightweight,...

Injection Moulding: The Versatile and Cost-Effective Manufacturing Solution

Injection moulding is a widely used manufacturing process that has revolutionized the production of plastic products. It is a cost-effective and versatile method that enables the creation of complex shapes and structures with great accuracy and consistency. In this article, we will explore the injection moulding process in detail, its...

Injection Moulding: The Process and Its Applications

Introduction Injection moulding has significantly transformed the manufacturing landscape since its inception in the mid-20th century. It is a versatile and highly efficient process that enables the production of a wide range of products with precision and consistency. From everyday items to critical components in industries, injection moulding plays a...

The technical basis of machining: production process and production type

Technology foundation The production process The process of machine production refers to the whole process of making products from raw materials (or semi-finished products). For machine production, it includes transportation and storage of raw materials, preparation of production, manufacturing of blanks, processing and heat treatment of parts, assembly and commissioning...

Design specifications and metal materials for die castings

Introduction Die casting is a versatile manufacturing process used to produce metal components with high precision and complex geometries. The success of the die casting process relies heavily on the design specifications and the choice of metal materials. In this comprehensive guide, we will explore the crucial factors involved in...

China die casting of quality, output and common problems

Development Prospect of Die Casting Die casting is a widely used manufacturing process for producing metal components with high precision and complex geometries. As the demand for lightweight and durable metal parts continues to grow in industries such as automotive, aerospace, electronics, and consumer goods, die casting holds a promising...

Applications and defects of die castings

Introduction Die casting is a widely used manufacturing process that involves injecting molten metal into a mold cavity under high pressure to produce complex metal components with excellent dimensional accuracy and surface finish. It finds extensive applications across various industries due to its versatility, cost-effectiveness, and ability to produce parts...

die casting zinc alloy comparison different process costs

Results and Discussion of Die Casting Zinc Alloy Introduction Die casting is a popular manufacturing process for producing metal components with high precision and complex shapes. Among the various materials used in die casting, zinc alloys offer unique advantages due to their excellent properties, cost-effectiveness, and ease of casting. In...

Brief introduction of die cast zinc alloys and test methods

Brief Introduction of Die Cast Zinc Alloys and Test Methods Introduction Die casting is a versatile and widely used manufacturing process that involves injecting molten metal into a mold under high pressure to produce intricate and high-quality metal components. Zinc alloys are one of the most popular materials for die...

The Benefits and Applications of aluminum alloy die casting

Introduction Aluminum alloy die casting is a widely used manufacturing process that involves injecting molten aluminum into a mold cavity under high pressure to produce intricate and lightweight metal components. This process offers numerous advantages, making it a popular choice for various industries. In this comprehensive blog post, we will...