Blog Center

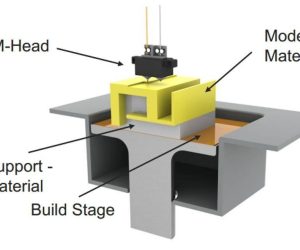

3D printing FDM technology to Help supply chain system

Today, many enterprises have begun to use 3D printing technology to improve supply chain management, optimize production, and achieve agile manufacturing. With a history of nearly 30 years, FDM technology has a wide range of applications, not only for product prototyping, functional testing, but also for manufacturing tools and final...

3D printing revolutionize the traditional supply chain model

In recent years, the world has witnessed a remarkable technological advancement known as 3D printing, or additive manufacturing. This groundbreaking innovation has the potential to revolutionize the traditional supply chain model, bringing about transformative changes in various industries. 3D printing has already proven its capabilities in producing intricate and complex...

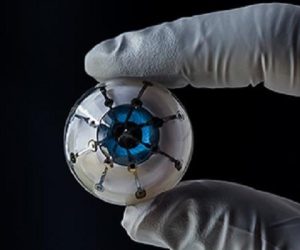

3D printing help blind people restore eyesight in medical treatment

3D printing technology helps blind people restore their eyesight in medical treatment,researchers believe that 3D printed bionic eyes can one day help the blind see or make them see more clearly.

3D printing technology applies mechanical gloves to print automobile parts

General Motors uses a variety of new technologies in its assembly plants, such as robotic arms and 3D printed parts. At the Michigan assembly plant, workers easily process 3D printed parts with the help of a mechanical glove called "roboglove". 3D printing parts save costs on the assembly line At...

Application of 3D printing fixture and fixture in automobile manufacturing industry

Fixture and fixture applications for 3D printing are rising in the automotive manufacturing industry, including:Signboard calibration, positioning device Production line workers usually use hand-held fixtures to manually affix vehicle identification and model name. Traditionally, this type of fixture will be a CNC machine tool made of metal, which is bulky...

Technical advantages of 3D printing in automotive equipment manufacturers

Technical advantages of 3D printing in automotive original equipment manufacturers 1

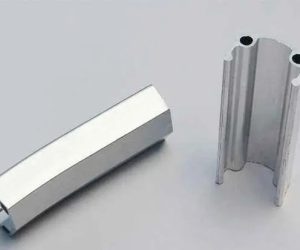

Why do we need to choose anodized aluminium for product manufacturing?

Anodizing technology is currently the most widely used and successful, and thanks to the development of this technology, anodizing alumina is used in many areas to enhance its texture and performance. V1 Industrial Internet is committed to helping mould manufacturers and major brands to save costs while creating high quality...

What are the benefits for using new Aluminium Alloy AD6 material?

Performance characteristics of the new aluminium ally AD6 are as follows: 1: Environmental testing: result in line with standards Introduction In the world of engineering and manufacturing, material selection plays a crucial role in determining the performance, durability, and cost-effectiveness of a product. Aluminium alloys have long been favored for...

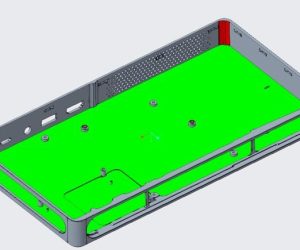

V1 Industrial Internet uses new aluminum alloy material AD68 research cases

V1 Industrial Internet uses "new aluminum alloy material AD68" new material research and development, professional mold design solutions customized a brand of projector, let me share the product features with you: 1. We made 1-1.5 degrees draft angle to the white side which is reduced the moldmaking cost by more...

Why do we need to use the new & anodic die-casting aluminium alloy?

In order to meet the challenges posed by the market, we had to meet the industry's needs with innovative technology, therefore we develop the new aluminium alloy material AD68 - this new material can solve industry pain points and process technology challenges, the advantages of the this new material are...

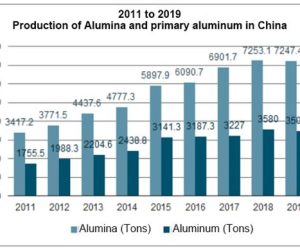

China Aluminum Industry Operation: midstream aluminium production is the core of the industry chain

According to the data of "China Aluminum Industry Operation Status and Investment Direction Analysis Report 2020-2026" released by Wise Research Consulting. China is a major producer and consumer of aluminium, with the world's largest production of alumina and primary aluminium. China's alumina and primary aluminium production in 2019 was 72.742...